Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

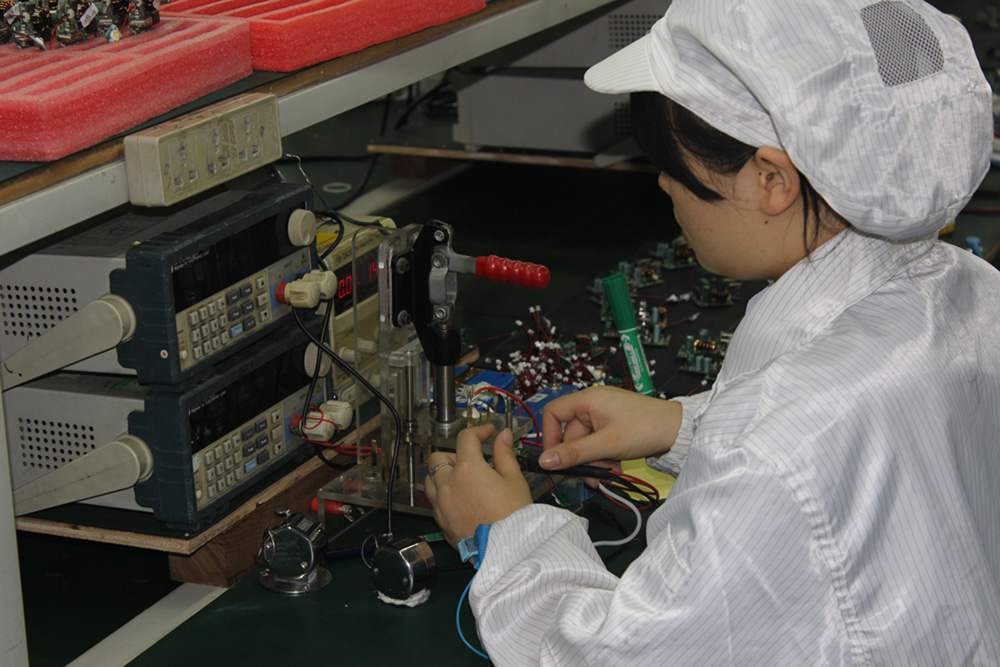

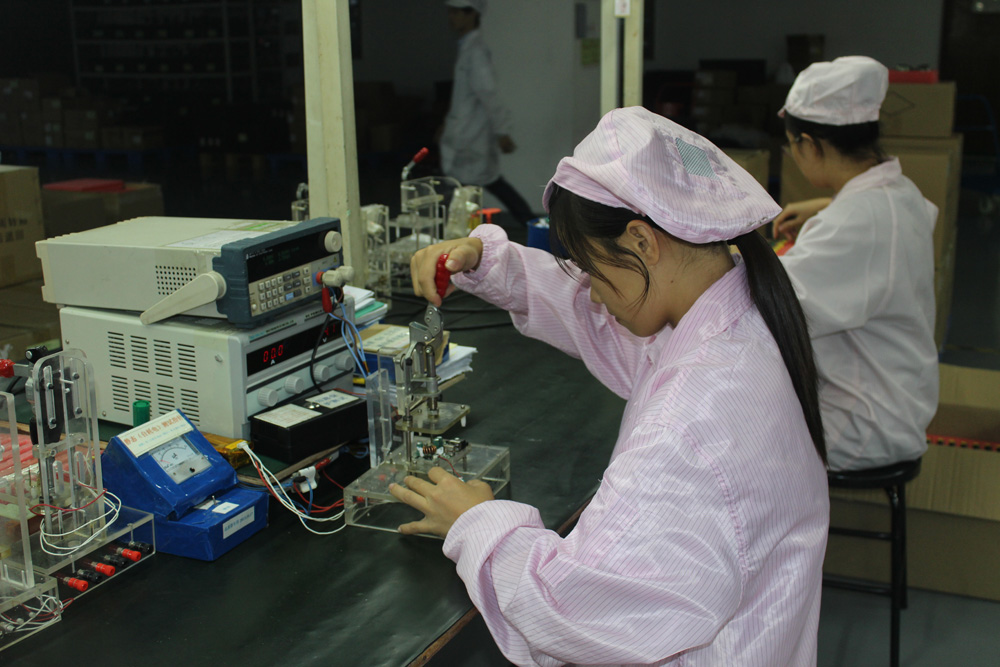

PCBA testing refers to the testing of IC programming, circuit continuity, current, voltage, pressure and other aspects of the PCBA board. There are many uncontrollable factors in the production process of PCBA. It is difficult to ensure that the PCBA is an intact product. PCBA testing is a necessary link to strictly control the quality of shipments.

After the PCBA has undergone a series of PCBA tests, the PCBA board without problems can be labeled as qualified, and finally can be packaged and shipped.

Author:

Mr. David Zheng

Phone/WhatsApp:

+8613723405434

New radiation-hardened chip from STMicroelectronics helps low-orbit satellites expand communications coverage and Earth observation services March 24, 2022, China – STMicroelectronics (ST; NYSE:...

Huizhou Liandajin Electronic Co., Ltd is a solutioner for high precision double-sided and multi-layer Printed Circuit Board(1-20 layers),the production process of printed circuit boards is many and...

Three key sectors: IC carrier board, automotive board, Miniled board IC carrier board: the first level packaging substrate with "technological homology" with PCB The IC carrier board is directly used...

The direct point of PCB Panel is to combine several small PCB units with various connection methods. The more common puzzles include AA sequential spelling, AB positive and negative spelling, AA...

Email to this supplier

Author:

Mr. David Zheng

Phone/WhatsApp:

+8613723405434

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

Fill in more information so that we can get in touch with you faster

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.